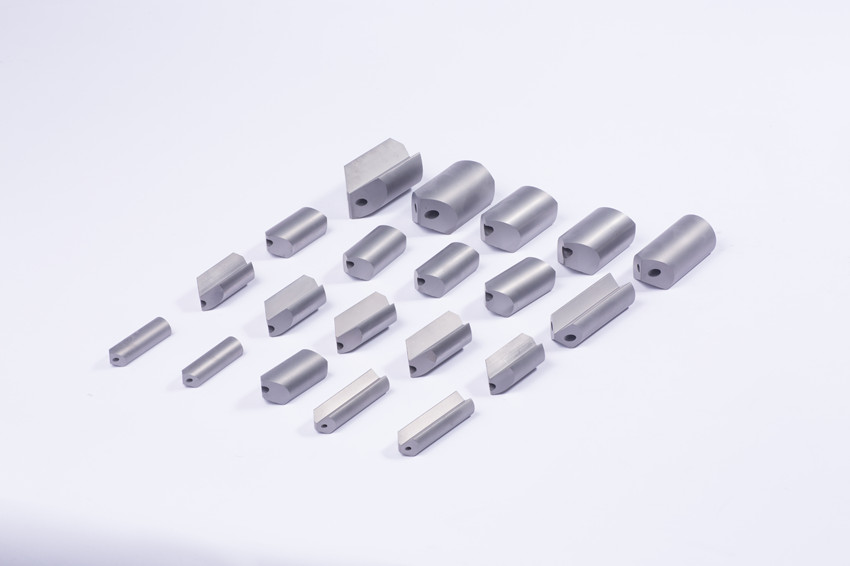

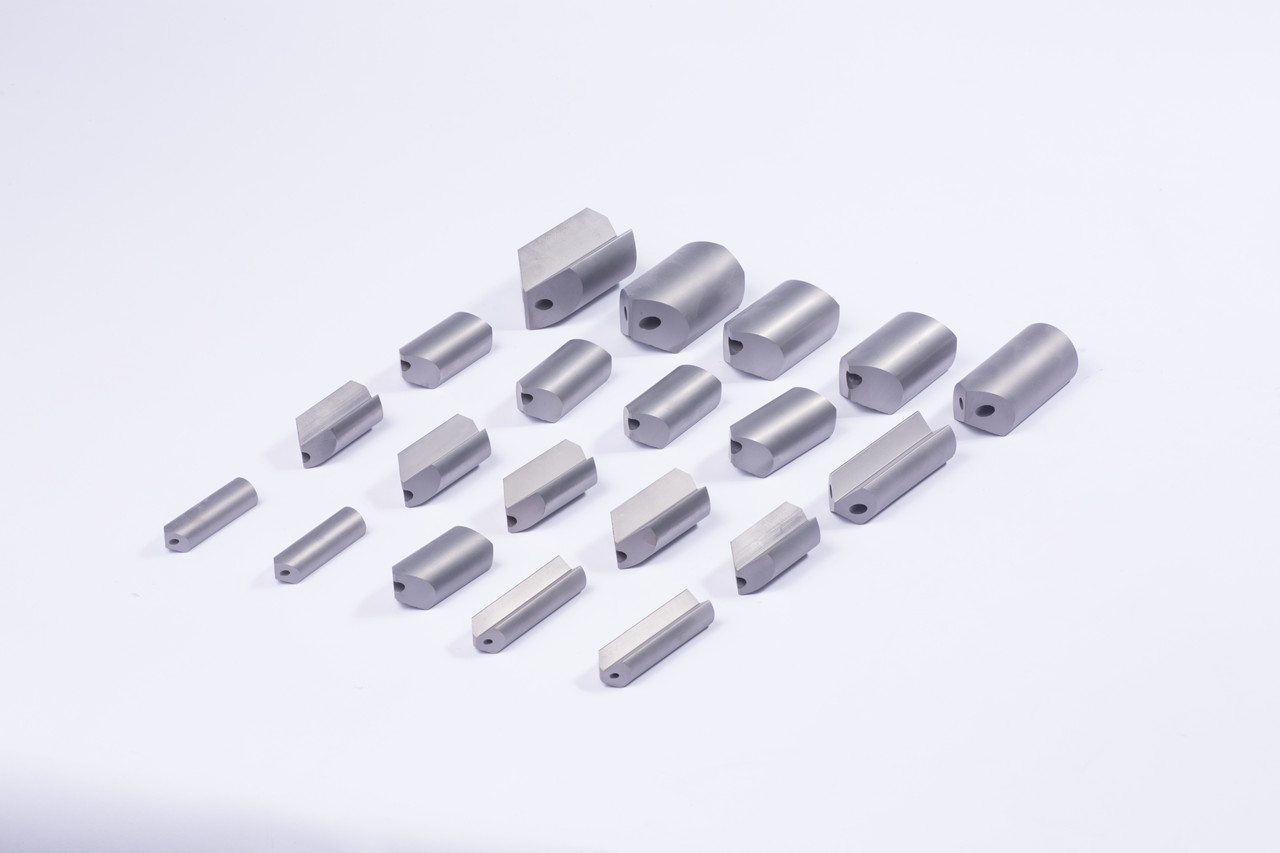

描述

Gun drill is a kind of extensively used hole-machining tool.There are two kinds of gun drills, namely, the center-cut gun drill used for drilling blind holesand the trepanning drill.

Requirement

Gun drilling is possible over a range of depths and diameters. For diameters between 1–3 mm, gun drilling can be performed successfully with special equipment. It is a common process between 3–50mm in diameter. It is also possible for the 50–75 mm range, however less efficient than BTA deep hole drilling.

With a standard twist drill, it is difficult to drill a straight and accurately sized hole of a depth more than about 5 times the diameter. This is a problem in many manufacturing processes, especially the firearms industry: the barrel of a gun must be very straight and accurately sized. Gun barrels are far longer than their inside diameter; as an example, the .223 inch (5.56 mm) caliber barrel of the M16 rifle is 20 inches (508 mm) long, nearly 90 times the diameter of the bore. The gun drill was developed to drill such long, straight holes.

Types

A gun drilling machine drilling holes in steel.There are three basic types of deep hole drilling. Processes are categorized by how the cutting coolant flushes heat and chips from the cutting face. The three types of deep drilling are:

Gun drilling – The cutting tool is a fluted solid rod that has a hole bored down the center. Coolant is pumped through a hole in the inside of the drill. It flows back outside the drill, through the flute, bringing the chips with it.

BTA / STS (Boring and Trepanning Association / Single Tube System) – The cutting tool is a tube. Coolant is pumped in around the outside of the cutting tool and carries chips out through the center tube. Because tubes have minimum sizes, this is only an acceptable technology for holes of over 15.6 mm in diameter.

Ejector system – The cutting tool is a tube with another tube nested inside. Coolant flows through the smaller tube to the cutting face and then coolant and chips flow back through the larger tube. This is only an acceptable technology for holes of over 18.4 mm in diameter.